Mitsubishi Motors Gives Australians What they Want: |

Mitsubishi Motors Gives Australians What they Want: |

Mitsubishi's new 3.8 litre V6 |

|

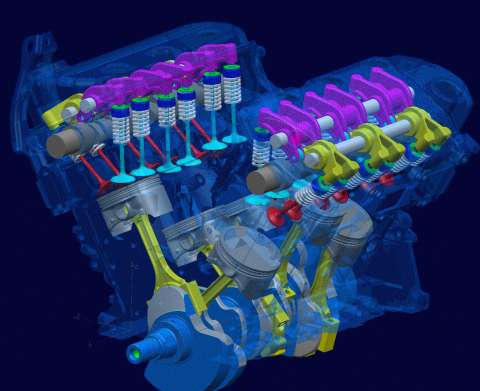

10th June, 2005 to Both Driver and Environment In its mission to develop ‘the best quality car ever built in Australia’, Mitsubishi Motors Australia Limited (MMAL) yesterday revealed crucial aspects of the new PS41’s new engine. Slated for an October 2005 launch, the PS41 offers strongly competitive power and performance features, while being the first Australian-built car to meet the new Australian environment regulations. “The PS41’s 6G75 engine is an almost total redesign of the 6G74 engine used in the XR Magna, but retains the strengths of the basic architecture of its predecessor,” says Tom Phillips, President and CEO, MMAL. “Through painstaking development and precise application of the most advanced management system, the PS41 engine provides the necessary durability to support our 5/10 warranty.” Engineered for Australians, the new Mitsubishi 6G75 is a 3.8 litre SOHC 24-valve MPI V6 engine. This efficient design with a state-of-the-art engine management system incorporates only 10% carry-over parts from the former 3.5 litre engine, and eliminates complications, such as double overhead cams, variable valve timing, variable intake manifold, secondary air system and an EGR system. The result is an engineering achievement without frills, enabling MMAL to focus customer value onto other design areas, such as the advanced trims and finishes. An Engine of Unprecedented Innovation

New engine developments include: Control Area Network (CAN): The PS41 is the first locally-built Mitsubishi to use Control Area Network (CAN) to link all major electronic control modules. It is a system of multiplexing information between electronic controllers, dramatically accelerating communication and reducing the number of wires. The returnless fuel supply system: Designed to reduce heat build-up in the fuel tank, it results in less vapour fuel emissions from the tank. 12-hole injector: Allied with the returnless fuel system, the high technology 12-hole injector is a crucial component to meeting the new Euro3 regulations and offering smooth driveability. It delivers a fine atomised spray pattern with a much smaller droplet size of 60-70 microns, almost vaporising the fuel. Fuel pump module: The new design integrates the pump, fuel filter, pressure regulator and fuel-gauge sender into one assembly, easing quality control of these critical components. Engine Management System (EMS): One of the most significant features of the new PS41 engine is the Engine Management System developed collaboratively with Robert Bosch and extensively tested in Australia, Japan, Germany and Switzerland. The major benefits derived from the system result from the highly efficient ‘torque-demand’ method of choosing the instantaneous settings for the engine variables, such as throttle valve position, injection time and ignition timing. Compared to a conventional system, with its computing power used up in deciding how to manage uncoordinated interactions between separate inputs, this system gives precise torque control in response to driver and system demands to give unparalleled drivability under all conditions. Valve Springs: MMAL applied Ralliart valve springs to the camshaft profile from the Ralliart Magna to ensure valve control and durability at the increased lift and high rpm. Wound from a special section-shaped wire, and then treated with shot preening and nitriding, the valve springs offer ultimate fatigue strength. Existing 6G74 engine strengths that have been incorporated into the 6G75

redesign include: Outside the base engine: The PS41 Accelerates its Environmental

Standards This new regulation requires a vehicle to have On Board Diagnostics (OBD)

that self-detect, at a minimum, any event that would lead to tailpipe emission

failure due to: In the event that any of these problems occur, the driver must be informed by means of a Malfunction Indicator (MIL) or malfunction indicator lamp. Additionally, the system must store fault codes to assist in subsequent diagnosis and repair. To prepare the engine to meet the new emission targets, special attention has

been paid to reduce the areas in which hydrocarbons can hide from the advancing

flamefront during combustion. After extensive testing, MMAL has reduced: These measures have resulted in a total reduced crevice volume, and thereby lower unburnt hydrocarbons to be attended to by the emission control system. Additionally, the PS41 complies with the new noise regulation – the ADR 83, which mirrors the existing European standard. The new standard requires the PS41 to meet a 3dB lower limit. This new noise limit reflects a 50% reduction in sound power over the previous ADR 28 noise regulation. The PS41 is the first Australian manufactured vehicle to comply with both the new emission and noise standards, while it’s totally new sweet sounding 3.8 litre engine has all the power, torque, flexibility, responsiveness, driveability and fuel economy to satisfy the toughest demands of Australian drivers. |

Mitsubishi's new 3.8 litre V6 |