|

NEWS ROAD TESTS |

Nissan's New Global Light Truck Platform |

|

|

NEWS ROAD TESTS |

Nissan's New Global Light Truck Platform |

|

HEAR MOTORING NEWS ON RADIO |

|

|

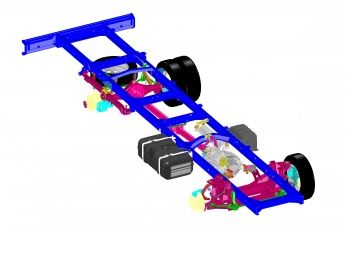

28th July, 2006 Nissan Motor Co., Ltd, has developed a new global platform for light duty trucks (LDTs) on which the new Cabstar will be built. The new LDT platform and a platform for panel vans, will replace Nissanís 11 unique LCV platforms by 2010 in order to maximise efficiency. Some LCVs will also continue to be built on passenger vehicle platforms. The new LDT platform was developed by Nissanís engineering division in Barcelona, Spain in collaboration with Nissan Motor Light Truck Co.ís engineering team in Japan. The platform will support Cabstar first, followed by a new generation of light duty trucks in the future. ďThe development and introduction of the new LDT platform demonstrates that Nissan is taking its place in the global commercial vehicle market very seriously. We are ambitious to succeed and we are confident that we will meet the needs of operators and drivers across the globe with the range of products that will be developed on the new platforms,Ē said Andy Palmer, corporate vice president of Nissanís LCV Business Unit. The new Nissan LDT platform will support Cabstarís award-winning full cabin over engine (COE) configuration, building on the Cabstarís reputation for excellent balance between load-carrying capacity and in-town manoeuvrability. ďIn developing this new platform, we kept our customers in the forefront of our mind and enhanced its ability to support vehicles that provide maximum performance in load capacity, manoeuvrability and cost of ownership,Ē said Palmer. Nissan engineers adopted a straight, light, but strong ladder frame design. The combination of COE configuration and a light and durable frame enhances Cabstarís load performance both in length and weight. This gives the customer the choice between greater load capacity and shorter vehicle length. It also enhances manoeuvrability when driving in cities because it allows operators to carry the same load capacity on a shorter wheelbase. Due to the Cabstarís new frame, it will be easier and quicker to operate on the engine during maintenance and repair. This operation is made even easier by the adoption of a tilting cabin configuration. Time off the road will be minimised, allowing maximum efficiency for the customer. The Cabstar platform has been reinforced to ensure a car-like crash performance. Independent tests have demonstrated that in the case of frontal impacts, Cabstarís safety level is as high as that of a passenger car. Safety was enhanced by reinforcing the front part of the frame and by enhancing the elasticity of the straight elements behind the cabin. Nissan has set ambitious commitments for its global LCV business, one of four breakthrough areas identified under the companyís Value-Up business plan. By fiscal year 2007, the company plans to double operating profit margin to 8% and grow volumes by 40% to 434,000 units worldwide compared with fiscal 2004. In fiscal 2005, ended 31st March, 2006, the Nissan LCV business sold 400,000 units, up 28% from the previous year. The unitís consolidated operating profit margin came to 7.7%. The Cabstar will continue to be manufactured at Nissanís plant at Avila, near Madrid, Spain. |

|

|